Sales hotline: +86-0412-3605066 3605055

Fax: +86-0412-3603118

Email: lhbgs.ok@163.com

Address: Tiexi Development Zone, Haicheng City, Liaoning Province

Website: www.lhdxgg.com/en/

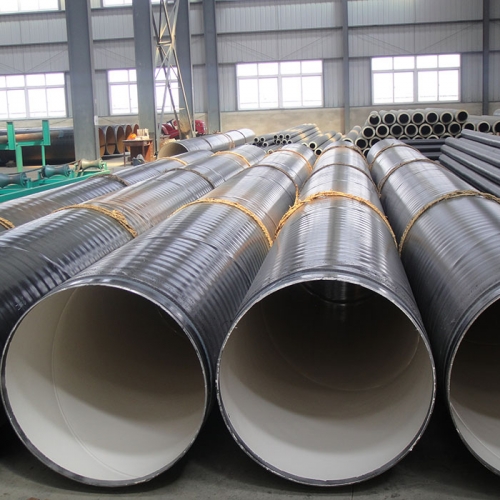

The material of spiral submerged arc welded pipe is a spiral welded steel pipe, which is made of strip coil as raw material and is often extruded at high temperature and welded by automatic double wire double-sided submerged arc welding process. The characteristics of submerged arc welded pipe are as follows: the production process of straight welded pipe is simple, the production efficiency is high, the cost is low, and the development is fast. The strength of spiral welded pipe is generally higher than that of straight welded pipe. It can produce welded pipe with bigger diameter with narrower blank, and welded pipe with different diameter can also be produced with blank of the same width.

(1) Weld clearance control device is used to ensure that weld clearance meets welding requirements, pipe diameter, offset and weld clearance are strictly controlled.

(2) Both internal and external welding are conducted by submerged arc welding with single or double wires using an electric welding machine to obtain stable welding specifications.

(3) The welds after welding are inspected by on-line continuous ultrasonic automatic damage instrument, which ensures 100% non-destructive detection coverage of spiral welds. If there are defects, alarm automatically and spray marking, production workers can adjust the process parameters at any time to eliminate defects in time.

(4) Air plasma cutting machine is used to cut the steel pipe into single pieces.

(5) After cutting into single steel pipe, the first inspection system of each batch of steel pipe head should be strictly carried out to check the mechanical properties, chemical composition, dissolution status, surface quality of steel pipe and non-destructive inspection to ensure that the pipe-making process is qualified before it can be put into production.

(6) Raw materials are strip coil, welding wire and flux. Strict physical and chemical tests are required before investment.

(7) Submerged arc welding with single or double wires is used for butt joint of strip head and tail, and automatic submerged arc welding is used for repair welding after coiling into steel pipe.

(8) Before forming, the strip is leveled, trimmed and planed, and the surface is cleaned, conveyed and bent.

(9) Using electric contact pressure gauge to control the pressure of the cylinder on both sides of the conveyor to ensure the smooth conveying of strip steel.

(10) Externally or internally controlled roll forming.