Sales hotline: +86-0412-3605066 3605055

Fax: +86-0412-3603118

Email: lhbgs.ok@163.com

Address: Tiexi Development Zone, Haicheng City, Liaoning Province

Website: www.lhdxgg.com/en/

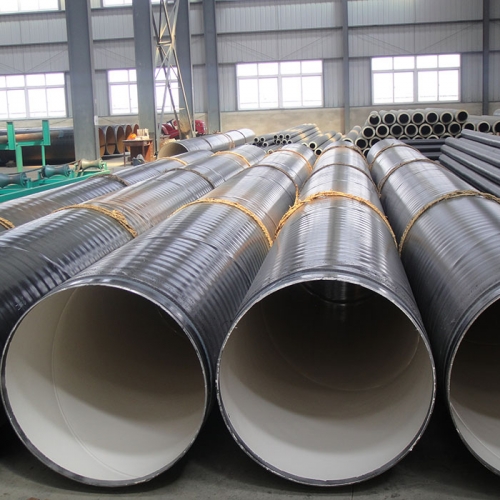

Technical Index of Double-sided Submerged Arc Welding Rotary Steel Pipe

Fatigue: Metal materials under the ultimate strength, long-term bearing the role of alternating loads (that is, the size and direction of repeated changes in the load), without significant plastic deformation and sudden fracture phenomenon, known as fatigue. Fatigue index includes fatigue limit and fatigue strength.

FATIGUE LIMIT: The maximum stress that a metal material can bear under repeated or alternating stresses is called the fatigue limit when the cycle (N) stress cycle does not break.

Fatigue strength: The maximum stress that a metal material can bear when it breaks after several cycles (N) under repeated or alternating stresses is called fatigue strength. At this time, N is called the fatigue life of materials. Some metal materials have no obvious fatigue limit under repeated or alternating stresses, which is commonly expressed as fatigue strength.

In the process of steel tube forming, the steel plate has uniform deformation, small residual stress and no scratch on the surface. The processed steel pipe has more flexibility in the dimension and specification range of the diameter and wall thickness of the steel pipe, especially in the production of high-grade thick-walled steel pipe, especially large-diameter thick-walled steel pipe, which has advantages that other processes can not match, and can meet more requirements of the users in the specification of the steel pipe.

Welding can be realized in the best position by pre-welding followed by internal and external welding (fine welding). It is easy to control the quality of welding because it is not easy to produce defects such as staggered edges, welding deviation and non-penetration.

The integral mechanical diameter enlargement can effectively improve the dimensional accuracy of steel pipe and the distribution of internal stress of steel pipe, thus avoiding the damage caused by stress corrosion, and is conducive to the field welding construction.

Nine 100% quality inspections were carried out to ensure the quality of submerged arc welded steel pipes under effective inspection and monitoring during the whole production process.

All the equipment of the whole production line has the function of networking with the computer data acquisition system, realizing the real-time data transmission, and collecting the technical parameters and quality indicators in the production process by the central control room.