Sales hotline: +86-0412-3605066 3605055

Fax: +86-0412-3603118

Email: lhbgs.ok@163.com

Address: Tiexi Development Zone, Haicheng City, Liaoning Province

Website: www.lhdxgg.com/en/

Process Flow of Double-sided Submerged Arc Welding Rotary Steel Pipe

Ultrasound inspection I: 100% inspection of inner and outer welds and base metal on both sides of welds of spiral steel pipe;

X-ray inspection I: 100% X-ray industrial television inspection of internal and external welds, and image processing system to ensure the sensitivity of flaw detection;

Diameter enlargement: The whole length of straight seam steel tube is enlarged to improve the dimensional accuracy of steel tube and the distribution of internal stress of steel tube.

Hydraulic test: The expanded steel pipe is inspected one by one on the hydraulic test machine to ensure that the test pressure meets the standard requirements. The machine has the function of automatic recording and storage.

Chamfering: The qualified steel pipe will be processed to meet the required pipe end groove size;

Ultrasound Inspection II: Ultrasound Inspection is carried out one by one again to inspect the possible defects of longitudinal welded steel pipe after diameter enlargement and water pressure.

X-ray inspection II: X-ray industrial television inspection and photography of weld seam of pipe end after diameter enlargement and hydraulic test.

Tube end magnetic particle inspection: This inspection is carried out to find the defect of the tube end.

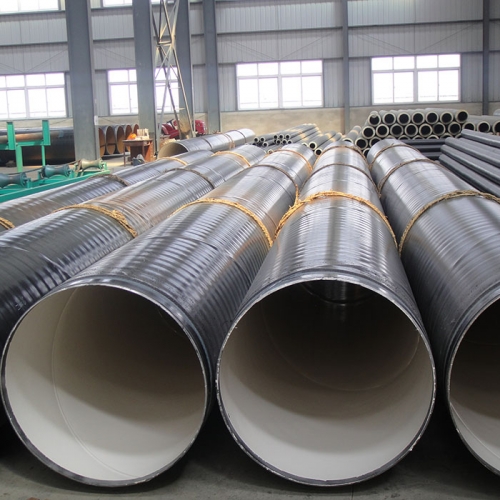

Anti-corrosion and coating: qualified steel pipes are anticorrosive and coated according to user's requirements.

In addition to the above testing items, according to API standards and other relevant standards and the special requirements of some users, it is necessary to carry out damage inspection and other tests on steel plates and steel pipes, including sampling inspection of physical and chemical properties of raw materials and 100% appearance inspection of steel plates.

Milling: Double-sided milling of steel plate edges by a milling machine to achieve the required width, parallelism and groove shape.

Pre-bending edge: Pre-bending edge by using pre-bending machine, so that the edge of the plate has the required curvature;

Forming: In JCO forming machine, first half of the pre-bended steel plate is stamped into "J" shape by several steps, then the other half of the steel plate is also bent into "C" shape, and finally the "O" shape of the opening is formed.

Pre-welding: to make the formed steel pipe seam and use gas shielded welding (MAG) for continuous welding;

Internal welding: longitudinal multi-wire submerged arc welding (up to four wires) is used to weld the inner side of the straight seam steel pipe; external welding: longitudinal multi-wire submerged arc welding is used to weld the outer side of the spiral submerged arc welding steel pipe;